All earthmoving equipment must have a service braking system – In the realm of earthmoving operations, safety is paramount. A crucial aspect of ensuring the well-being of operators and the integrity of equipment lies in the implementation of reliable service braking systems. All earthmoving equipment must be equipped with these systems to comply with legal regulations and minimize the risk of accidents.

This comprehensive guide delves into the intricacies of service braking systems for earthmoving equipment, exploring their legal requirements, types, design, maintenance, troubleshooting, operator training, and real-world case studies. By understanding these essential components, stakeholders can ensure the safe and efficient operation of earthmoving equipment, fostering a culture of safety and productivity.

Service Braking System Regulations

Earthmoving equipment is required by law to have a service braking system that meets specific performance standards. These regulations are designed to ensure the safety of operators and others working in the vicinity of the equipment. Failure to comply with these regulations can result in fines, penalties, or even criminal charges.

Penalties for Non-Compliance

- Fines ranging from hundreds to thousands of dollars

- Suspension or revocation of operating licenses

- Imprisonment in severe cases

Types of Service Braking Systems: All Earthmoving Equipment Must Have A Service Braking System

There are several different types of service braking systems used in earthmoving equipment, each with its own advantages and disadvantages.

Hydraulic Brakes

- Advantages: Powerful, responsive, and reliable

- Disadvantages: Can be complex and expensive to maintain

Air Brakes, All earthmoving equipment must have a service braking system

- Advantages: Less complex and less expensive to maintain than hydraulic brakes

- Disadvantages: Less powerful and less responsive than hydraulic brakes

Mechanical Brakes

- Advantages: Simple and inexpensive to maintain

- Disadvantages: Less powerful and less responsive than hydraulic or air brakes

Design and Functionality

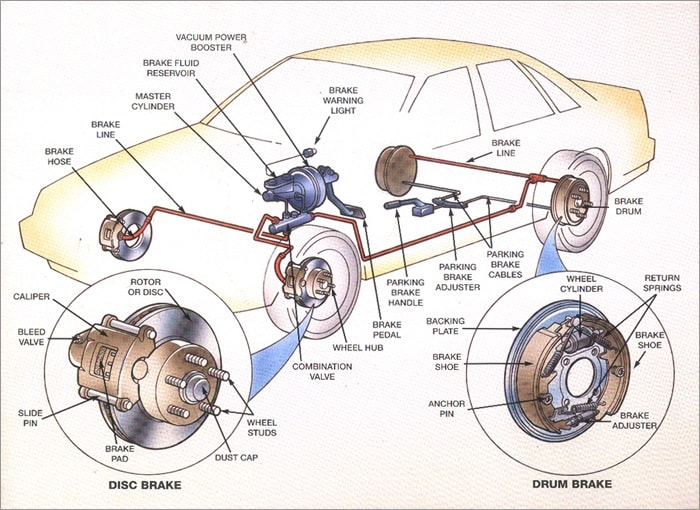

A typical service braking system consists of the following components:

- Brake pedal

- Master cylinder

- Brake lines

- Brake calipers

- Brake pads

- Brake rotors

When the operator presses the brake pedal, the master cylinder sends hydraulic fluid to the brake calipers. The calipers then squeeze the brake pads against the brake rotors, which slows or stops the wheels.

Here is a diagram of a typical service braking system:

Maintenance and Inspection

Regular maintenance and inspection are essential for keeping service braking systems in good working order. The following are some of the most important maintenance procedures:

- Check the brake fluid level regularly and add fluid as needed.

- Inspect the brake pads and rotors for wear and replace them as needed.

- Bleed the brake system to remove any air bubbles.

- Inspect the brake lines and hoses for leaks and damage.

The following are some of the most important inspection points:

- Brake pedal travel

- Brake fluid level

- Brake pad thickness

- Brake rotor thickness

- Brake line condition

Troubleshooting and Repair

The following are some of the most common problems that can occur with service braking systems:

- Spongy brake pedal

- Brake pedal pulsation

- Brake noise

- Brake fade

- Brake lockup

The following are some troubleshooting tips and repair procedures:

- If the brake pedal is spongy, it may be due to air in the brake lines. Bleed the brake system to remove the air.

- If the brake pedal pulsates, it may be due to warped brake rotors. Replace the brake rotors.

- If the brakes make noise, it may be due to worn brake pads. Replace the brake pads.

- If the brakes fade, it may be due to overheating. Allow the brakes to cool down and then inspect them for damage.

- If the brakes lock up, it may be due to a problem with the brake master cylinder. Replace the brake master cylinder.

Operator Training

Proper operator training is essential for the safe and effective use of service braking systems. Operators should be trained on the following topics:

- How to operate the service braking system

- How to identify and troubleshoot common problems

- How to perform basic maintenance

Case Studies and Examples

The following are some case studies and examples of accidents or incidents involving service braking systems on earthmoving equipment:

- In 2017, a dump truck driver was killed when the brakes on his truck failed. The truck rolled down a hill and crashed into a building.

- In 2018, a bulldozer operator was injured when the brakes on his bulldozer failed. The bulldozer rolled over and crushed the operator’s leg.

- In 2019, a crane operator was killed when the brakes on his crane failed. The crane collapsed and fell on the operator.

These case studies and examples highlight the importance of proper maintenance and inspection of service braking systems on earthmoving equipment.

Questions Often Asked

Why are service braking systems mandatory for earthmoving equipment?

Service braking systems are legally required to ensure the safe operation of earthmoving equipment, preventing uncontrolled movement and potential accidents.

What are the different types of service braking systems used in earthmoving equipment?

Common types include hydraulic, mechanical, and air-over-hydraulic systems, each with its own advantages and disadvantages.

How often should service braking systems be inspected and maintained?

Regular inspections and maintenance are crucial to ensure optimal performance and prevent system failures. The frequency of inspections and maintenance varies depending on the equipment and operating conditions.